Modular Prefab Steel Structure Welded H Section Steel Workshop With

Crane Beam Large Span Energy Saving

Project information:

Modular Prefab Steel Structure Welded H Section Steel Workshop With

Crane Beam Large Span Energy Saving

Steel structure nowadays is used much more widely in many

areas,here are some main addvantages of Portal Frame Steel

Structure:

1. Seismic resistance: steel structure of the roof mostly is slope

roof, the use of H section steel beam, roof purlin, knee brace and

other components compose a solid triangle shape, this structure

system has a stronger ability to resist the seismic and horizontal

load, suitable for seismic intensity of 8 degrees or more in the

area.

2. Wind resistance: steel structure has light weight, high

strength, good overall rigidity and strong deformation abilities.

The body weight of the building is only one fifth of that of the

brick and concrete structure. It can withstand a hurricane of 70

meters per second, so that life and property can be effectively

protected.

3. Durability: The steel skeleton of light steel structure is made

of super anticorrosive galvanized sheet, which effectively avoids

the influence of corrosion during construction and increases the

service life of light steel components. The structure can last up

to 100 years.

4. Sound insulation: The sound insulation effect is an important

index to evaluate the housing. The Windows installed by the light

steel system are all insulating glass, which has good sound

insulation effect, and the sound insulation can reach more than 40

decibels. The wall composed of light steel skeleton and sandwich

panel, its sound insulation effect can be up to 60 decibels.

5. Health: dry construction, reduce waste caused by pollution to

the environment, housing steel structure materials can be 100%

recycled, other supporting materials can also be most recycled, in

line with the current awareness of environmental protection; All

materials are green building materials, which meet the requirements

of ecological environment and are conducive to health.

6. Comfort: Light steel wall adopts high efficiency and energy

saving system, has breathing function, can adjust indoor air dry

humidity; The roof has ventilation function, which can form a

flowing air space above the interior of the house to ensure the

ventilation and heat dissipation requirements inside the roof.

7. Short construction period: all dry operation construction, not

affected by environmental seasons. For a building of about 300

square meters, only five workers can complete the whole process

from foundation to decoration in 30 working days.

8. Environmental protection: Materials can be 100% recycled, truly

green and pollution-free.

9. Energy saving: EPS, PU, rock wool, glass wool sandwich panels

have good thermal insulation, heat insulation, sound insulation

effect, can reach 50% energy saving standards.

Name | Modular Prefab Steel Structure Welded H Section Steel Workshop With

Crane Beam Large Span Energy Saving |

Structure Type | Gable frame, single ridge, clean span or two spans |

Length Scope | 50- 150m |

Width Scope | 20-50m |

Eave Height Scope | 10m |

Roof Slope | 10-15% |

Gable Wall Column Spacing | 7.5m |

Roof | Sandwich panel or single layer steel cladding sheet |

Wall | Sandwich panel or single layer steel cladding sheet |

Door | Sliding door, roller door, lifting door. |

Window | Fixed window, sliding window |

| Ventilator | Unpower ventilator, electric ventilator, fans |

Material list and technical parameters for such kind of steel

buildings:

| Steel Frame | H section steel | Q235/Q355 steel 8mm/10mm |

| Welding | Automatic submerged arc welding |

| Rust removal | Sand blasting |

| Surface finish | Alkyd paint or galvanized |

| Intensive bolt | M20,Grade 10.9 |

| Supporting System | Angle brace | L50x4,Steel Q235, processed and painted |

| Horizontal brace | Φ20, Steel Q235, processed and painted |

| Column brance | Φ20, Steel Q235, processed and painted |

| Tie rod | Φ89*3, Steel Q235, processed and painted |

| Ordinary bolt | M12 Galvanized bolt |

| Roof | Purlin | C160*60*2.5,Steel Q235, galvanized and painted |

| Roof panel | Sandwich panel or corrugated steel sheet |

| Sky light | 1mm thick PVC |

| Accessories | Glass cement, self-tapping screws, etc. |

| Edge cover | 0.4mm steel sheet profile trimming |

| Gutter | 0.4mm thick sheet steel profile or galvanized sheet |

| Down pie | Φ110PVC |

| Walls | Purlin | C160*60*2.5,Steel Q235, painted |

| Wall | Sandwich panel or corrugated steel plate |

| Accessories | Glass cement, self-tapping screws, etc. |

| Edge cover | 0.4mm steel sheet profile trimming |

| Ventilation | Powered Ventilation ball |

| Doors & windows | Rolling door/sliding door PVC/alu/steel/window |

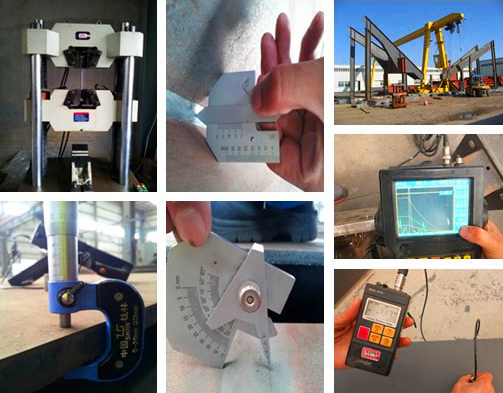

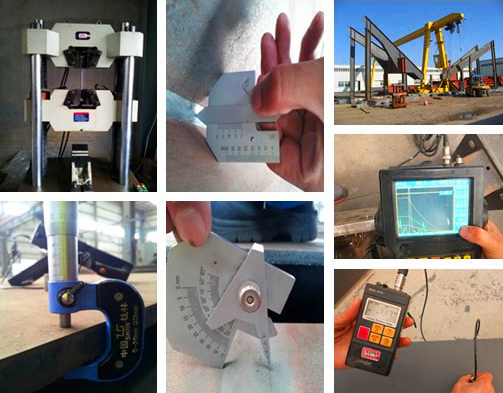

Steel structure fabrication factory:

The floor space of our steel structre fabrication factory is

35,000㎡, and the workshop area is 20000㎡. We own three light/heavy

H steel production lines, BOX production lines, C/Z purlin

production lines and various types of profiling steel sheet

machines with advanced equipment such as plasma cutting machine.

Our service:

1. Structural steel fabrication, painting , galvanizing ,

pre-assembly

2. Designing, fabrication and installation for Prefabricated steel

structure building.

3. Deepen or design the fabrication drawing or shop drawing based

on your architectural drawing and construction drawing

4. Engineering consulting service

Structural steel fabrication quality control:

100% testing dimension tolerance <1mm

20% sample welding line ultrasonic testing, no fault, full

penetration.

20% magnetic powder testing, no bubble, no defect, Smooth and Full

Supply third-party inspection assistance.

Packing and transport:

All the structure components, panels,bolts and sort of accessories

will be well packed with standard package suitable ocean

transportation and loaded into 40’HQ.

All the products are loaded at the loading site of our factory

using crane and forklift by our skilled workers,who will prevent

the goods to be damaged.